Printserver for Productive Printing

Printserver for Productive Printing

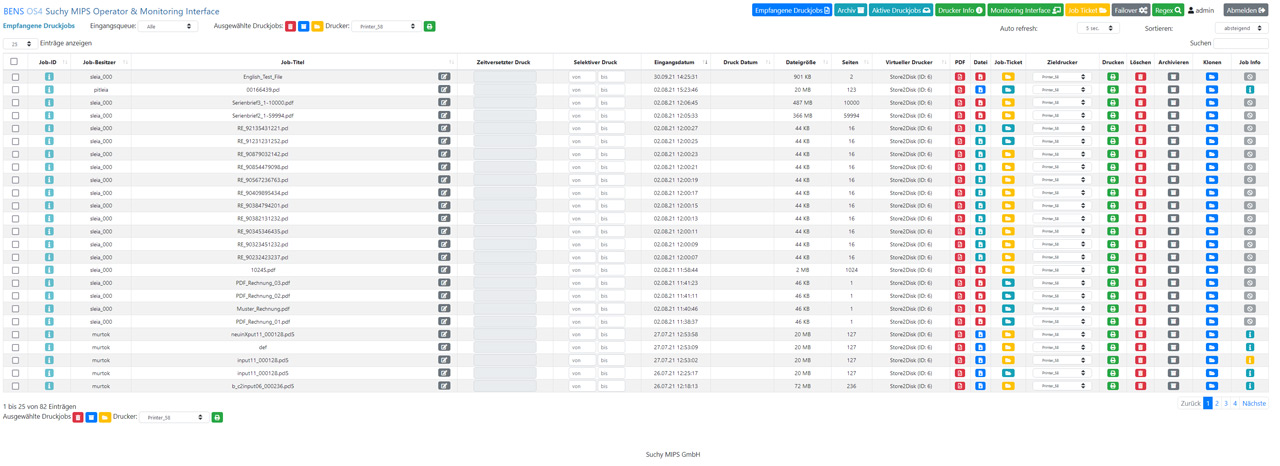

Overview of incoming print jobs

The operator sees all incoming print jobs. The print jobs can be identified by their characteristics such as job ID, job owner, job title. Different sorting and filtering criteria for the print jobs listing increase the operators work efficiency.

Free printer selection

The operator can determine on which printer the selected print job is to be output.

Preview of received print jobs

While the print jobs are spooled on the server, a preview (PDF) is automatically created. The preview gives the operator better possibilities to identify or check individual print jobs.

Scheduling for execution of the print jobs

Print jobs can be collected and output with a time delay. The operator can specify a separate start time for each print job. For example, the output of larger print jobs can be shifted to the night and thus the efficient utilization of the printers can be increased.

Jobticket

With BENS PP Spool, job tickets that contain processing instructions for the printer can be created and assigned to print jobs. Job tickets are reusable, so that, for example, a job ticket defined once can be assigned to different print jobs. Example: a defined brochure print on A4, folded to A5 with saddle stitching can later be applied to other print jobs.

The operator can select the appropriate or requested finishing from the job ticket repository. Print jobs can be grouped and assigned the same job ticket. This saves time in print job configuration and increases work efficiency.

Archiving the print jobs

All print jobs are archived after their output. The amount and duration of archiving print data is freely configurable. The archive offers similar functions as the module with incoming jobs, such as print preview, sorting and display of jobs according to various criteria.

Reprint

The operator has the possibility to reprint print jobs from the archive. In doing so, a different target printer than the one originally selected can be used. This function is particularly useful if, for example, the printer has a defect during printing that cannot be repaired in the short term, but the entire print file has already been transferred to the printer and is therefore lost for the printing process in most cases.

A great feature is the partial reprinting. Here, the pages to be reprinted are specified by a page range from – to definition. This procedure saves valuable time and paper.

Estimated remaining time of the printout

A time bar shows the operator the estimated remaining time for the respective print job. With this information, the operator can optimally plan his time and work effectively.

Various print formats

BENS PP Spool is not fixed to a concrete print format, but can process different print formats, such as PCL5, PCL6 (PCLXL), Postscript and PDF. This gives your company great flexibility in preparing print data. Service providers can accept differently prepared print data from their customers and process them further with BENS PP Spool.

Various input channels

The BENS PP Spool Server accepts print jobs via different print protocols, such as Socket, SMB, IPP, IPPS, LPR (optionally also IPDS). The processing of documents from a so-called hotfolder is also supported. Hot folders are particularly suitable for mass processing of PDF documents. The user saves the time that he loses when opening and printing the PDF files, because he can store all PDF files to be printed in the hotfolder, from where they are automatically fetched by the BENS PP Spool Server and stored in the printer queue.

A job ticket can be used to define the kind of processing of the PDF files from the hotfolder (e.g. brochure printing).

Process automation (workflows)

In addition to the definition of job tickets, which define the processing in the printer, simple to complex workflows can be implemented, which define a complete processing of incoming documents. A simple workflow would be e.g. the addition of letterheads, GTC’s and barcodes. In a complex workflow, for example, print data could be additionally archived, media types defined for different document areas and logs stored in a share directory.

Load balancing

The BENS PP Spool Server provides a function to automatically distribute the print load to several printers. With this function, single print jobs as well as equal copies of single documents can be distributed efficiently to different printers.

Reliability

For all printers that have been created on the BENS PP Spool Server, substitute printers can be defined according to priority, to which the print jobs are automatically forwarded in case the original target printer should fail. Every printer created on the BENS PP Spool Server can be defined as a substitute printer. A whole chain of substitute printers can be defined – all printers created on the server are available for this purpose.

This procedure guarantees a safe printout even if, for example, printing is done without supervision during the night and the entire production should be available on the next morning.

Mass printing

The BENS PP Spool is particularly suitable for mass printing on fast production printers. Both print jobs with a large number of pages and many small print jobs with few page numbers can be processed. If many small print jobs have a negative influence on the print speed of the printer, then such print jobs can be combined to one large print job by workflow.

Various output channels

The BENS PP Spool Printserver supports different output channels, such as socket, SMB, IPP, IPPS and LPR. In addition, the print jobs can also be stored on an external directory or sent via e-mail.