Case Studies

Custom filters and plugins are programs implemented for the BENS Server according to special requirements of the customer. They partly consist of standard components (filters and plugins), but are supplemented by special functions.

Here we present some such implementations as case studies. This way you can get a feeling for what is possible by using a BENS server with appropriate filters and plugins.

If you would like to automate a document workflow and are not sure whether this would be possible with a BENS plugin, then please call us or write to us. Explain us your requirements and problems you would like to solve. Our workflow specialists will advise you in detail and work out a solution together with you.

We support our partners in an advisory capacity in the areas of printing from SAP systems, such as the integration of OMS systems, large Windows printing environments, as well as in the implementation of production printing solutions for special work processes tailored to the customer.

Starting with the determination of necessary actions, through the project phase to the realization, we advise our customers individually and target-oriented.

We are also happy to provide support, i.e. we monitor projects planned by you, so that you can concentrate on your core tasks.

Due to our many years of experience in the area of networks and virtualization environments, our customers also like to turn to us for larger and / or hard-to-locate printing and network problems.

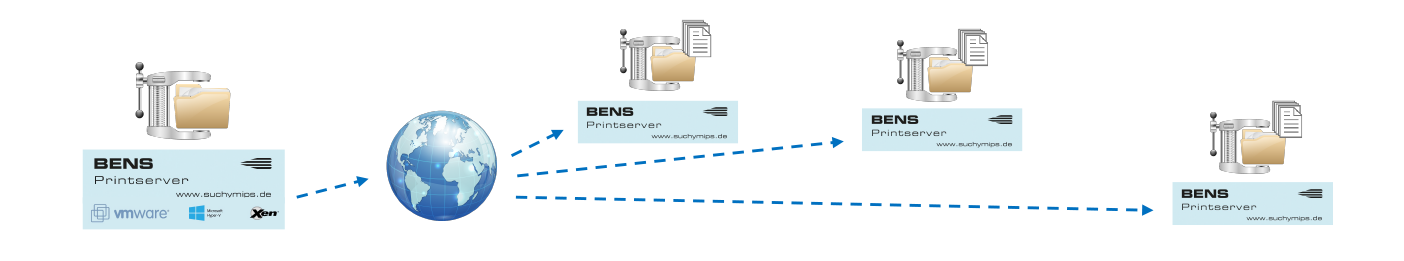

Compress and send print data

- The customer operates more than printers at about 100 locations. The print data is generated centrally and sent to the site printers via dedicated lines.

- The customer previously used the Citrix’s Thinprint solution, but was dissatisfied with it. He cited the complicated operation and high price as the reasons for his dissatisfaction.

- At the customer’s headquarters, 2 virtual BENS VMWare appliances were installed in master/slave configuration on which printer queues were set up for all target printers.

- In some, few branches, BENS G4 Turbo was used.

- BENS G4 Lite was used in most branches.

- The DataCompress Filter was installed on all Printserver queues.

- The DataCompress Filter compresses the print data in the head office and decompresses it in the locations.

- The compression ratio is between 1:8 and 1:10.

- With this solution, the customer increased print performance through fast data transmission and data security through compression.

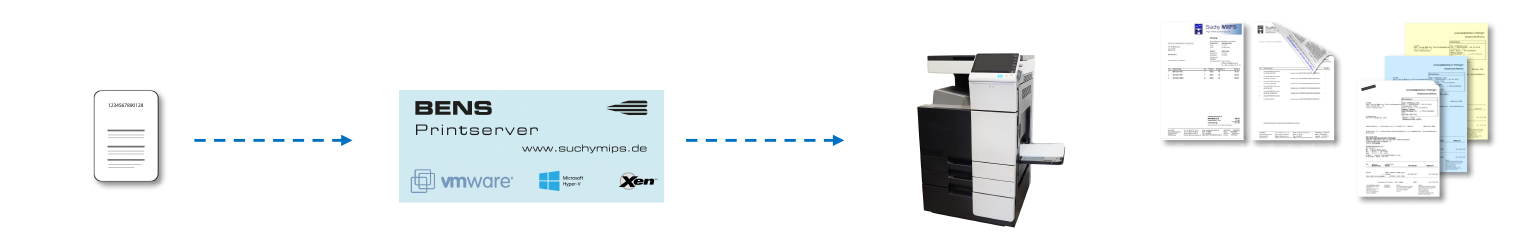

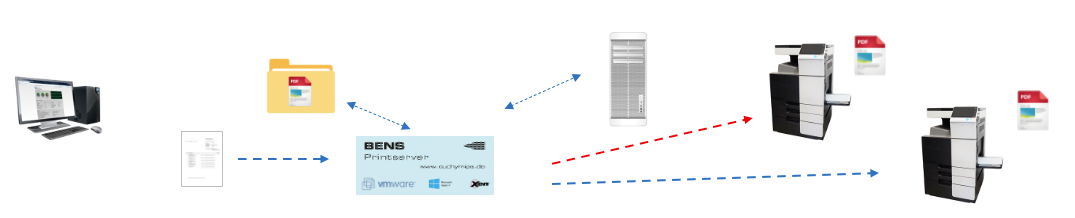

Convert print jobs to PDF and send via e-mail

- The customer wants to print invoices for accounting purposes only. The invoices to the customer are to be emailed as PDF files. However, the customer does not want to change anything in his ERP system.

- The invoices are sent by the clerk from the ERP system to the BENS Printserver.

- The plugin on the BENS Printserver examines the print data to find out the name of the sender.

- The invoice is printed on a printer that is located in the accounting department.

- At the same time, the invoice is converted into PDF and sent back to the sender of the print job via e-mail, so that he can check the invoice again and forward it to the final recipient.

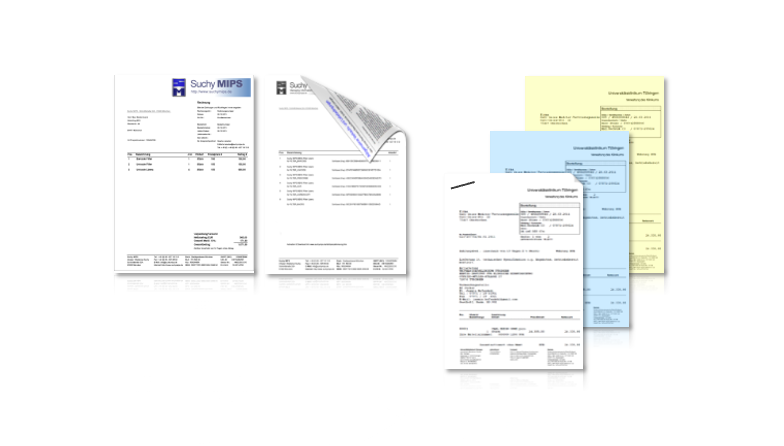

Replace dot matrix printers with MFP's

- The customer used to print his business documents (delivery bills, invoices, order confirmations, etc.) on 3-ply paper on dot matrix printers with an EPSON emulation. He wanted to switch to modern colour printers, but without having to change anything in his ERP system.

- Letter templates for the customer’s business documents and general terms and conditions were digitized with the MacroGenerator Enterprise and stored as PCL macros on the BENS Printserver.

- The plugin on the BENS Printserver converts the EPSON print data into PCL-5.

- Overlays with the document templates are added to the converted PCL contents with the BENS Macro Filter. The general terms and conditions are printed on the first back side.

- With the CarbonCopy filter electronic “Carbon copies” – 3 copies per sheet – are generated.

- Each “Carbon copy” is marked with a colour stripe.

- All the “Carbon copies” are printed stapled together.

Overlay, Carbon Copy and other plugins

- The customer prints documents for drivers who deliver goods. An automatic batch run produces all documents that are needed for a so-called tour (daily routes).

- The plugin on the BENS Printserver first collects all print jobs.

- The collected print jobs are sorted by the criteria “driver name” and “customer number”. The “Driver name” and “Customer number” are read out from the print job by the plugin.

- Each document is copied 3 times.

- Each copy is provided with a stapling command.

- On all front pages of the first copy the watermark “Customer” is added.

- On each back page the customer’s terms and conditions are printed.

- On all pages of the second copy the watermark “Clerking” is added.

- On all pages of the third copy the watermark “Accounting” is added.

- The text and position of the watermarks are variable and controlled by a configuration.

- A yellow sheet from tray 2 is printed between each document with the same driver name.

- After the driver name is changed, a blue sheet is printed from tray 3.

- If no further print job follows within a certain period of time, which is defined in the configuration file, then the tour is completed. All print jobs are sent to the KM box in the specified order. To avoid mixing the tour jobs with jobs from other print queues, all print jobs of a tour are merged into one spool file and only then sent to the printer.

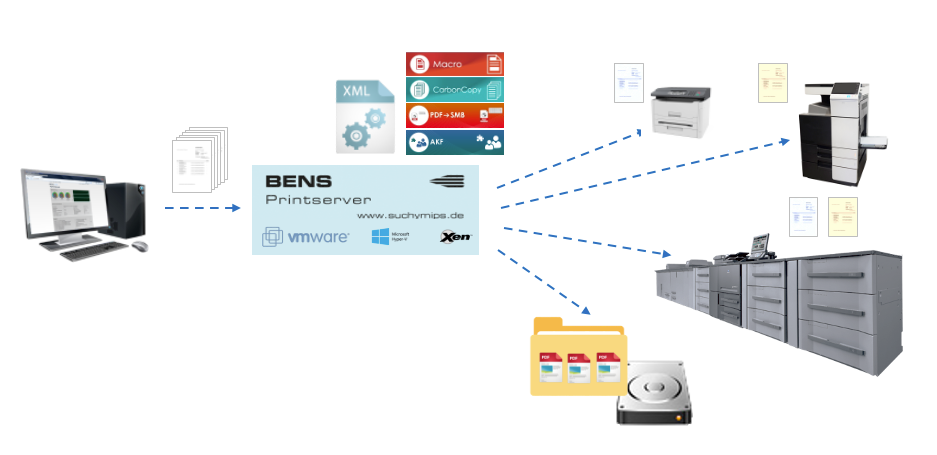

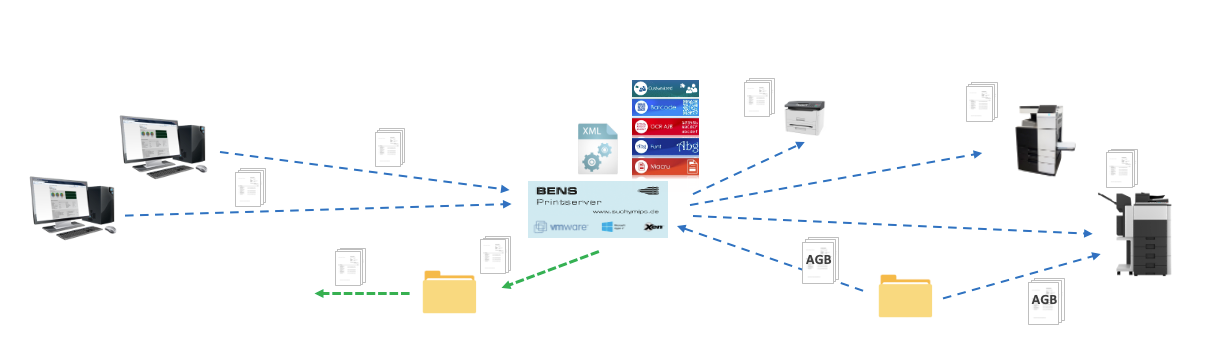

Overlay, Carbon Copy, Print Job Distribution and more …

- The holding company prints business documents for several companies belonging to the holding.

- For each company, their Letterheads and terms and conditions are printed as overlays on the documents using the Macro Filter. Depending on the company, different workflows are executed. The print data is additionally converted to PDF and stored on a network share.

- The workflow determines

- Which stationery is printed as overlay

- Which general terms and conditions are printed

- How many copies are made

- Which printer is used for the output

- Which paper trays are used

- Whether and which final processing should take place (e.g. stapling).

- The respective workflow is defined in the plugin configuration.

- Depending on the company and language, a suitable printer and paper tray is controlled.

- The plugin on the BENS Printserver analyses the incoming print data to identify company and language.

- From the configuration, the workflow is read out for the determined combination company/language: Overlays, copies, finishing, target printer, paper trays, etc. and implemented accordingly.

- A copy of each print job is stored as a PDF file in a network share. The file name is formed from the transmitted triggers.

SAP printing with barcodes, overlays, etc.

- The customer operates approx. 300 printers from his SAP system

- All print jobs are controlled via the BENS Printserver

- Plugins on the BENS Printserver:

the PCL Barcode Filter adds barcodes

the Macro Filter adds suitable overlays (macros) and logos

the Macro Filter adds GTC’s in suitable language on the back side of the last page

Print EAN-13

- The customer wanted an EAN barcode on some printed documents for a specific clientele.

- The client number is searched for in the print data stream.

- The client number found is compared with numbers from a table. The table is located in a hotfolder and is regularly maintained by the customer.

- If the client number is found in the table, then the plugin continues to search for a trigger agreed with the customer “EAN:” followed by a 13-digit number.

- This number is converted to an EAN-13 barcode and inserted into the print data stream. The trigger with the 13-digit number is deleted from the print data stream.

- The position where the barcode should be printed is read from the configuration file by the plugin.

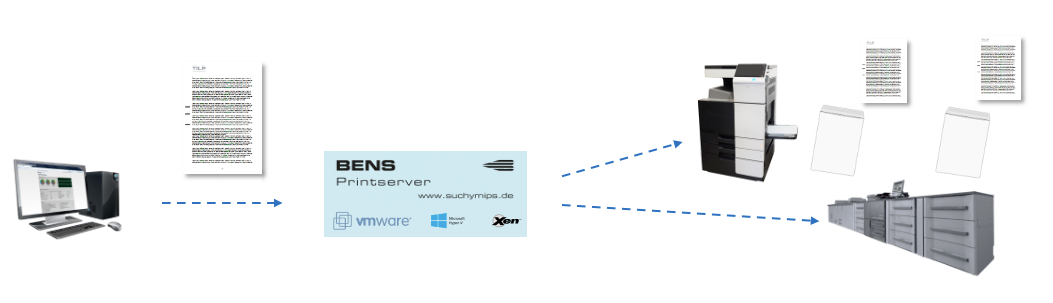

Print OMR

- The filter on the BENS Printserver prints on each front side of the incoming PCL5 print jobs a so-called OMR marking for the inserting system SI 3300 from manufacturer Hefter.

- The form and position of the marking follows the rules defined in the specification of the manufacturer.

- The workflow provides that the page sequence is coded consecutively with 3 bits (values from 0 to 7).

- If the capacity of the envelopes is exceeded, the document is sent to another printer. The available capacity of the envelopes is configurable.

- The current sequence counter is stored on the BENS server and used as start sequence for the next print job, because a continuous numbering – also after interruptions or switching off the inserter – was desired.

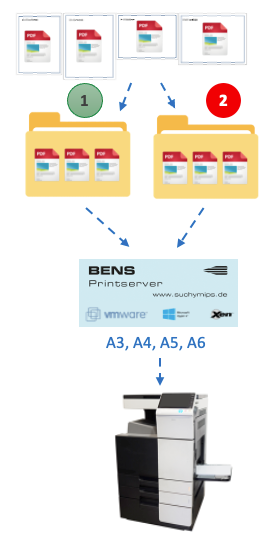

Scale PDF

- The customer receives PDF files from various sources.

- The PDF documents have different sizes, most of which do not correspond to the standard paper sizes that are in the printer. The printer stops before printing and asks to specify the desired paper.

- A hotfolder was created in the project, in which the PDF files are stored.

- The plugin on the BENS Printserver fetches the PDF files from the hotfolder and checks their size.

- If the size corresponds to one of the standard formats A3, A4, A5, A6, then the file is sent directly to the printer.

- If the size does not correspond to any of the standard formats, then the PDF is scaled so that the page image fits onto one of the standard formats. When scaling, the aspect ratio of the original file is kept. Then the PDF file is sent to the printer.

- PDF files that must not be scaled are stored in a second hotfolder.

- The plugin on the BENS Printserver scales the page content in such a way, that it fits to the next largest standard page format.

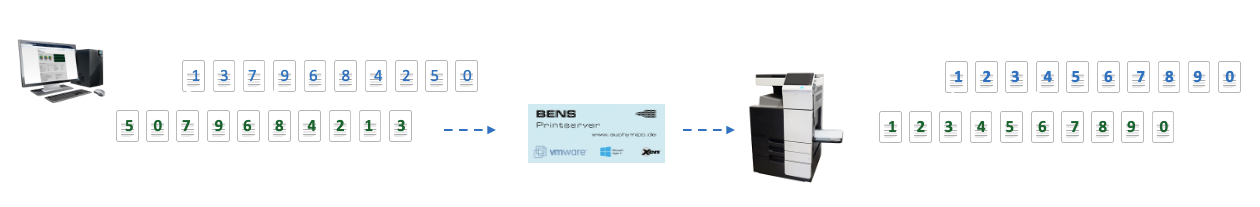

Print and sort tax assessment

- More than 30 clerks of the customer print tax assessments on the same printer. Each tax assessment consists of 10 to 30 individual print jobs. Before the project was implemented, the print jobs of individual clients were mixed together and had to be laboriously sorted apart after printing. The customer wanted a solution that prevents the mixing of the print jobs and keeps the printouts for individual clients clearly separated.

- The plugin on the BENS Printserver collects print jobs and sorts them by tax number.

- All print jobs with the same tax number are merged to one print job. The process for a particular tax number is finished as soon as no print jobs with the same tax number are found after a certain period of time.

- At the beginning of each print job a sheet with the text “Start tax number XXXX/YYYY” and at the end with the text “End tax number XXXY/YYYY” is added.

- As soon as a print job with a tax number is finished, it is sent to the printer.

Split PDF files

- The customer generates PDF files containing several documents. The individual documents are to be stapled.

- There is – always at the same position – a barcode on the last page of each individual document.

- The plug-in on the BENS Printserver searches for the barcode on each page.

- The page on which a barcode is found is identified as the last page of the current document.

- The PDF file is split into individual documents.

- Each document is provided with a stapling command for the Konica Minolta Bizhub C308 printer and then sent to the printer.

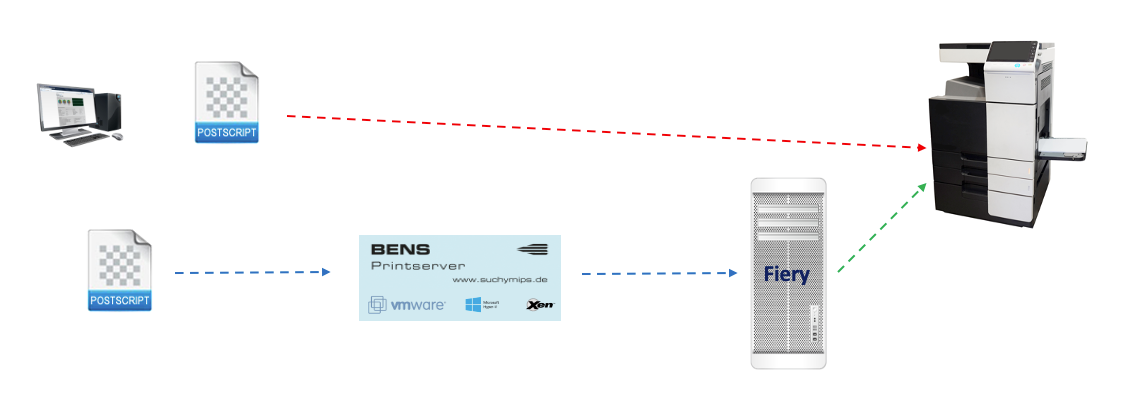

Convert PS to Fiery PS

- The filter on the BENS Printserver converts Postscript print data with printer-specific instructions into a Postscript format defined by EFI with printer-specific instructions for the Fiery controller IC417.

- The printer specific instructions are among other things the specification of paper sources, setting of the duplex / simplex mode, stapling etc. These are not part of the Postscript page description language and are implemented by the printer manufacturer.

Just-in-time document printing on the assembly line

- The customer produces devices on an assembly line. He wants that at the end of the assembly line for each arriving device the appropriate documents are in the output tray of the printer, which is placed next to it.

- During the processing, the customer’s application sends a job to the BENS Printserver, which contains the number of the document set to be prepared.

- After receiving this job, the plugin on the BENS Printserver reads the list of related documents (PDF files) from an external database of the customer, copies the documents from the external repository and prepares the PDF files for printing.

- The clerk scans a barcode during the assembly of the devices.

- The information decoded from the barcode is automatically sent to the BENS Printserver. After receiving this information, the plugin sends the documents already prepared for printing directly to the printer.

- If the printer fails, then optionally the BENS Failover System automatically takes over and sends the print data to a predefined alternative printer.

Print labels just-in-time

- The customer supplies spare parts for cars. Until now, the packages containing the spare parts were not labeled. The customer wanted a suitable label with item number, item description, quantity and delivery note number on the packaging of each individual part.

- The application sends a list of all items to be delivered together with the delivery note to be printed.

- The delivery note is printed immediately.

- The plugin on the BENS Printserver generates a label from the data of the list, which is first temporarily stored on the BENS Printserver.

- If a spare part is packed, then the clerk scans a barcode that is located next to the packed part on the delivery note.

- The decoded data from the scanned barcode is read into a web dialog window and forwarded to the BENS Printserver.

- After receiving the barcode data, the plugin prints the appropriate label on a label printer.

- The just-in-time printing of the label ensures that the correct label is always stuck on the packaging.

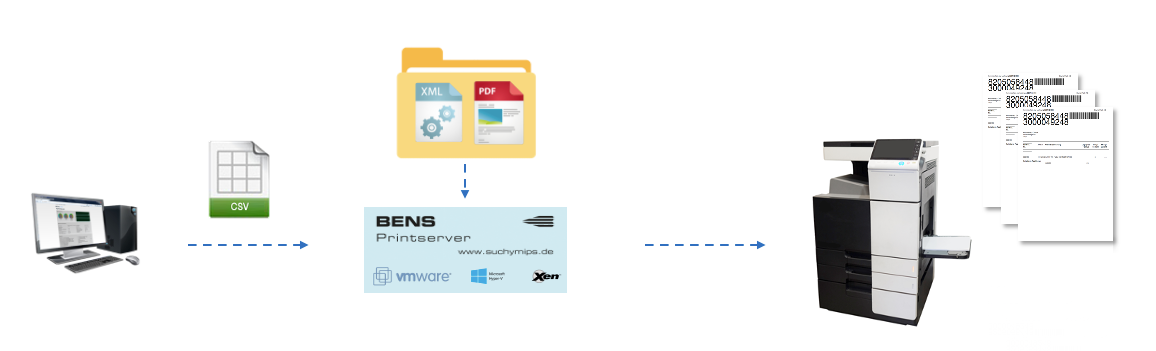

Automatically fill forms with data from CSV data

- The customer’s application sends CSV files to the BENS Printserver. The CSV files contain a header line with field names, among others the name of the form to be used.

- The plugin on the BENS Printserver fills the corresponding form with the data from the CSV file and sends it finally to the printer.

- The CSV files may contain several data records. From each data record a filled form emerges.

- The forms are available as PDF files with fields and are previously uploaded to the BENS Printserver or optionally kept in a hotfolder.

IntelligentDuplexer

- The plugin is designed to improve performance when printing so-called mixplex documents, i.e. documents that contain both simplex and duplex pages.

- On some printers the change from simplex to duplex takes – due to mechanical reasons – a few seconds, which leads to the printer printing much slower than expected if there are a large number of changes from simplex to duplex and vice versa.

- The plugin converts all simplex pages to duplex pages to eliminate the time loss when switching from simplex to duplex and vice versa.

- To achieve optimal performance, the plugin checks – taking into account various parameters, such as print speed simplex, print speed duplex, time delay when switching from simplex to duplex, computing time of the program, etc. – whether the change to a pure duplex document results in a performance improvement.

- If the result is positive, then the conversion is made.

- The conversion of simplex pages to duplex is done in a way that prevents the counting of blank back pages. For this purpose, controller switch 33 must be set to 1 on KM PP machines. For printers that do not support this option, a filter option can be set that results in a real, physical blank page being inserted.